Looked at from a certain angle the Kalmar DCG160 does look racy and has a work performance to back that up

Now we’re having a play with the DCG160.

As its name suggests, it has a 16-tonne capacity, with a 600mm load centre.

It stands out as bright as any fire engine, and in some lights you may mistake it for a Ferrari: imposing without being obnoxious. Or perhaps not quite.

Anyway, the carriage and fork attachments are matte black, with thick cylinders; it’s a tough-looking machine on the outside, but with a sensitive interior.

More about that soon.

Engine

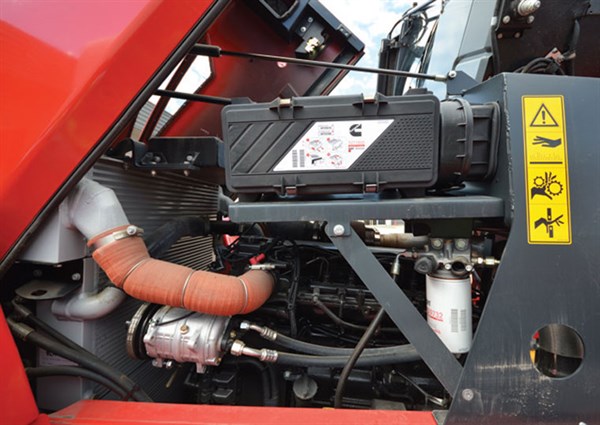

The DCG160 comes with a choice of engines, Cummins or Volvo and, breaking it down further, customers can choose either the 3A, 3B or 4 Final.

We’re looking at the smaller option, the Cummins 3A (129kW).

Cab and Controls

This ‘G’ Series forklift has evolved the CANbus and the cab.

The CANbus provides the driver with multi-system monitoring, via a small driver’s screen mounted on the dash.

It’s the amount you can do with this one small screen where the real innovation lies.

All diagnostics are done through this driver’s screen.

It’s called the common electrical control system, and it’s now exclusive to all ‘G’ Series Kalmar machines.

Okay, so you’ve found your fault using the driver’s screen.

Great, but what can you do about it?

Well, say for instance your lift lever breaks as you’ve got a load of timber suspended on the forks over the yard.

The mini-levers are busted and aren’t communicating with the carriage.

On the ‘G’ Series you can use the driver’s screen to operate the mechanical components and bring the forks down.

In essence, you manually force the function into action.

There are two CANbus systems: a J1939 from the engine and transmission, and a Kalmar system that links into other Electronic Control Modules (ECMs) around the forklift, and the whole system is connected in a loop.

Another feature Kalmar are proud of in their ‘G’ Series range is the new ‘EGO’ cabin.

It’s hard to find a forklift company these days that doesn’t boast that their cab is the finest, most luxurious driving environment on the planet, so I always approach these things with a little scepticism.

It’s a spacious cab; you could almost invite visitors in (not recommended).

There’s no steering column going down to the floor, which gives extra leg room, and if you find yourself with a Phillips head screwdriver, a lull in the workload and sufficient motivation, you can adjust the angle of your pedals.

There is a fabric, low-back seat today but a high-back, leather seat can be optioned.

On your right is what’s known as the ‘canoe’.

It’s the armrest that houses all the mini-levers and controls that you’ll use, other than the gear-shifting stick — in its traditional home to the left of the wheel.

The canoe is able to float forwards or backwards, and the levers can tilt towards your palm. It’s easily launched.

These features mean the cab can be set-up for each person’s size and preferences, and then easily adjusted when a new person jumps in.

While there is no overhead guard, drivers are protected by a 6mm sheet of Lexan. Front, side and rear vision is provided by thick, laminated glass windows. Vision in all areas is excellent.

Performance

The DCG160 accelerates smoothly, beginning slow, as you would expect, but getting up a good head of steam fairly quickly. But what impressed me was its ability to stop in a hurry, without fuss. It didn’t lurch forward when called to halt or throw me around in the seat.

It does wonders for driver confidence knowing a machine like this will yield so willingly to your commands.

Lifting is slower than a smaller forklift, of course, but is smooth and reliable.

On reaching full height the mast gives an almighty jolt, which shudders the entire machine, reminding you of the sort of weight you’re dealing with here.

The turning circle is much tighter than you would expect for a machine or this size, and unlike a 2.5-tonner you never feel as though you might tip the thing over.

Service

Service interval is 500 hours and the good stuff is accessed by manually cranking up the cab, which takes one minute of arm pumping exactly. You can option an automatic system, if you don’t fancy a workout.

You’ll only need to go underneath to change the brake calliper pads and drain the oil (although you can option a hose that drains the oil out to a point behind the back wheel).

Verdict

Like everything European, you’re going to pay a bit more. But are you paying for quality here?

The answer appears to be yes, especially when you analyse the components separately.

You’re buying a modern machine with a CANbus system that will take some learning for service technicians, but could well save your bacon at some stage.

Specifications

Make/model: Kalmar DCG160 forklift

Lifting capacity: 16,000kg

Truck length: 5,305mm

Truck width: 2,540mm

Height, basic machine, ego cabin: 2,920mm

Wheelbase: 3,500mm

Turning radius, outer — inner: 4,785 — 420mm

Ground clearance, minimum: 350mm

Lifting height: 5,000mm

Mast height, minimum: 4,195mm

Mast height, maximum: 6,695mm

Length of fork arm: 1,200mm

Service weight: 19,200kg

Tyre type: Pneumatic

Number of wheels, front — rear: Four — two (front driven)

For the full review, pick up the May issue of ATN. Find out how here.