The heavy-duty diesel Mitsubishi Grendia FD70N forklift is built to deliver sturdy, energy efficient and remarkable performance, but even better — no numb bums

The first thing you notice about the Japanese-made Mitsubishi FD70N is its compact dimensions relative to load capacity.

The overall length to fork face is just 3,592mm.

Yet the height to the overhead operator guard with mast lowered is 2,610mm, so the vehicle looks shorter than it actually is.

Stability is not an issue as dual front wheels are fitted, bringing the maximum width to 2,173mm.

Sensibly, Mitsubishi has fitted the same 8.25–15–12PR pneumatic tyres (solid optional) front and rear with vacuum-assisted self-adjusting drum brakes all-round.

Operator safety is Mitsubishi’s number one priority so the FD70N is fitted with IPS or Integrated Presence System.

Catchy name, but the mast and transmission are linked to the operator’s seat.

If the operator stands up the mast and transmission are deactivated, though if the vehicle is on a slope it will still move due to gravity.

Cab and Controls

The driving position itself is simply brilliant on the Mitsubishi FD70N. Access to the seat is encouraged from the left but the right side is still uncluttered for alternate access.

A well-positioned grab handle on the A-pillar and non-slip step pads make climbing up to the cab easy.

Mitsubishi has also tackled bum-numbing drives with its FD70N. The combination of fully floating power train and suspension seat reduce transmitted vibration to the extent where it’s sensed rather than felt.

Though Mitsubishi’s beautifully balanced 6 cylinder S6S engine has a lot to do with this.

The S6S has plenty of grunt down low, just where it’s needed for moving the full 7-tonne rated load plus dry vehicle weight of 9.5 tonnes.

Once seated with the lap sash seat belt clipped in the high driving position gives excellent vision down to lowered fork level or over counterweight.

Just in case an operator backs up too close to a wall the tail lights are recessed into the counterweight.

To the left of the steering wheel with its rim knob are the mechanical handbrake and a bank of indicator lights (such as neutral position) and to the right an instrument panel containing warning lights for engine overheat and low oil pressure, parking brake and glow plug on and an hour meter and fuel gauge.

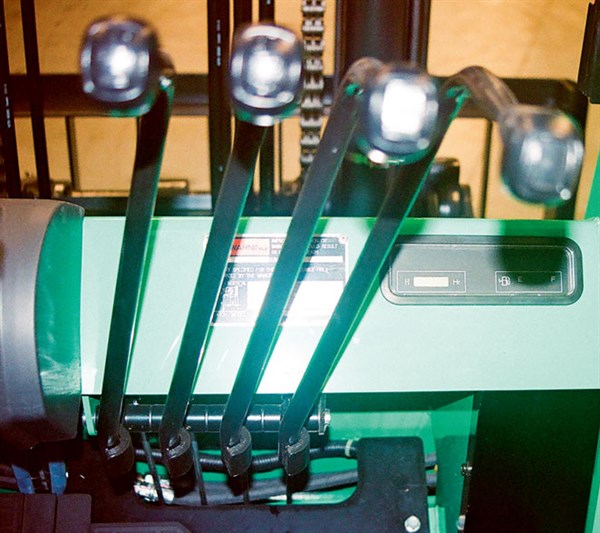

Standard are four levers in the normal position: fork raise and lower, mast tilt, fork side shift and an auxiliary control for a prong rotator with the hydraulics for this plumbed in.

Atop the operator guard is a clear acrylic rain cover that’s plumbed to drain down the left A-pillar to the wheel arch. No dumping of rain on your lap when running down a slope.

Both A-pillars have the normal lights for low light or night time operation.

Servicing

It just gets better. By lifting the Mitsubishi FD70N’s seat base, the S6S is revealed in all its glory, right back to the aluminium-cored radiator that’s more efficient at heat dissipation than a copper cored unit and cools not only the engine but also the hydraulics.

The muffler, just outside the radiator, gets additional cooling from the massive fan.

The battery and exhaust manifold are to the left of the engine. Mitsubishi stuck with a 12-volt system for easier component replacement.

The cyclonic air cleaner is to the right, indicating the FD70N was clearly designed for right-hand drive. If you’re transporting a load down a soft-shouldered road outside a factory, the air intake will be operating in cleaner air at the centre of the road, a small point but an example of Mitsubishi’s attention to detail.

Also to the right are the intake manifolds and fuel pump with injectors. The huge canister oil filter is fitted on its side so that when the oil is changed it won’t dump all over a workshop floor.

Ahead of the rear-hinged shroud is a removable metal floor and rubber mat to directly access the transmission and diff. With these removed and the shroud hinged up, servicing access is the best I’ve ever experienced in a forklift, reducing servicing technicians’ time to get on with the job.

We all know time is money when it comes to servicing downtime.

Servicing intervals are every 500 hours or six months with a three-year or 3,000-hour factory warranty.

Performance

With my foot firmly on the brake, I released the well-placed handbrake and selected forward, which engaged with barely a clunk.

At about 10km/h it shifted positively into second gear and I accelerated to about 15km/h.

Mitsubishi claims top speeds of 22km/h laden and 28 unladen, but 15 was plenty fast enough in that car park.

The brakes worked quickly with just gentle pressure, so standing on the brake pedal to stop the machine wasn’t needed. In the open the exhaust noise levels were sufficiently low not to affect my tinnitus but ear muffs may be needed in a factory.

Having a relatively short wheelbase, the ride was a bit choppy over the undulating concrete surface but the suspension seat eliminated any shocks through my bum flab.

In reverse the demo unit changed up at about the same speed and by using the steering wheel knob and turned to look over my shoulder the vehicle could be positioned exactly where wanted.

The combination of short wheelbase, light hydraulic steering and tight turning radius were great for reaching cargo in tight spots.

The engine torque kept the vehicle turning without needing any throttle opening, so my foot could be kept over the brake pedal.

Lifting

Because of the massive bottom end torque of the engine, on level ground I could inch the forks into the pallet without using the inching pedal, instead applying varying pressure on the main brake pedal.

In my opinion being able to keep my foot on the brake at all times was safer than using accelerator and inching pedal, though on up slopes this combination would be needed.

The lift and mast controls fell to hand and with the high seat position I could clearly see the forks for inching into the pallet.

A gentle raise, mast back slightly, then onto the accelerator for rapid lift or lower. The overhead guard rails and clear roof panel didn’t affect my view of the cargo.

The S6S responded instantly each time without hesitation and I even placed the pallet on the ground where directed without the slightest bump.

Verdict

There has been a hell of a lot of effort put into designing and engineering the Mitsubishi FD70N. Its ergonomics will reduce operator fatigue and the easy servicing access will save a lot of wasted time.

The S6S engine and 2-speed powershift are way better than just a single speed torque converter and I really liked having two speeds in reverse as well as forward.

Specifications

Make/model: Mitsubishi Grendia FD70N

Maximum load: 7 tonnes at 4.5m mast height, 5.6 at 6m

Load centre: 600mm

Maximum fork height: 3,300mm

Free fork height: 220mm

Maximum fork length: 2,500mm

Mast tilt: 12 degrees back, 22 forward

Maximum mast reach: 4,580mm

Maximum grade ability: 33 per cent

Turning radius: 3,310mm

Wheelbase: 2,300mm

Ground clearance: 170mm

Dry machine weight: 9.47 tonnes S6S maximum output: 67.7kW (90.8 brake horsepower) @ 2,300rpm

Maximum torque: 290Nm @ 1,600rpm

Piston displacement: 4,996cc

Fuel tank capacity: 130 litres