Wright takes to turbines for battery recharging solution

|

|

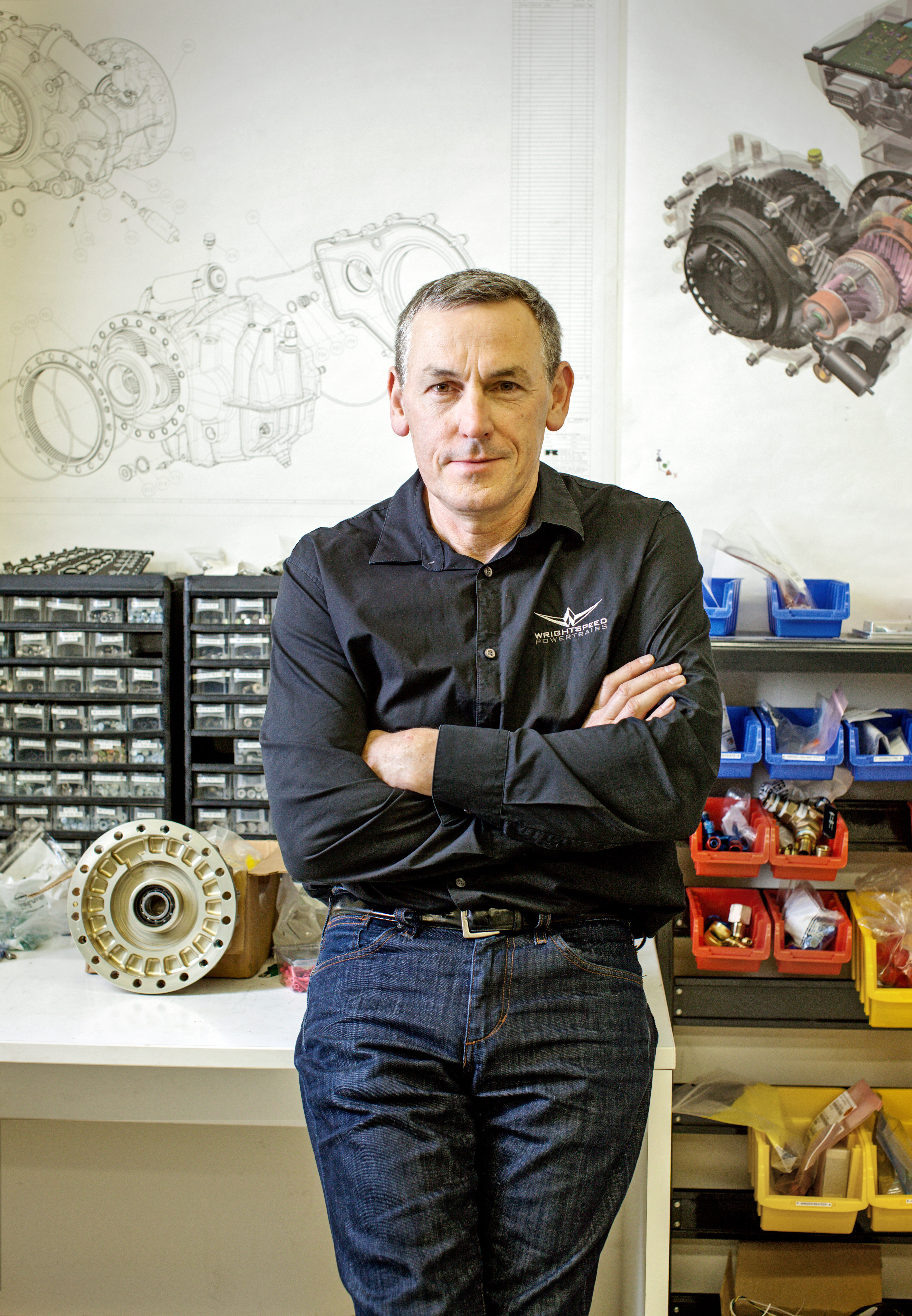

Electric vehicle visionary Ian Wright, founder of Wrightspeed

|

One of the world’s leading electric vehicle innovators, Tesla co-founder Ian Wright, has developed a cleaner electric solution ready for Australia’s trucks.

Wright left Tesla more than a decade ago to develop the world’s fastest street-legal electric car, the X1, and after ticking off that milestone, turned his attention to heavy vehicles.

Now heading up electric powertrain company Wrightspeed in the US, his sights are set on a cleaner, more efficient future for heavy vehicles.

A key sticking point in the vehicle electrification space, Wright points out, is emissions based on the average mix of power generation across nations.

If 37 per cent of the world’s electricity comes from burning coal, and ‘dirtier’ countries like Australia rely on coal for 63% of energy needs, a plug-in EV isn’t all that clean after all.

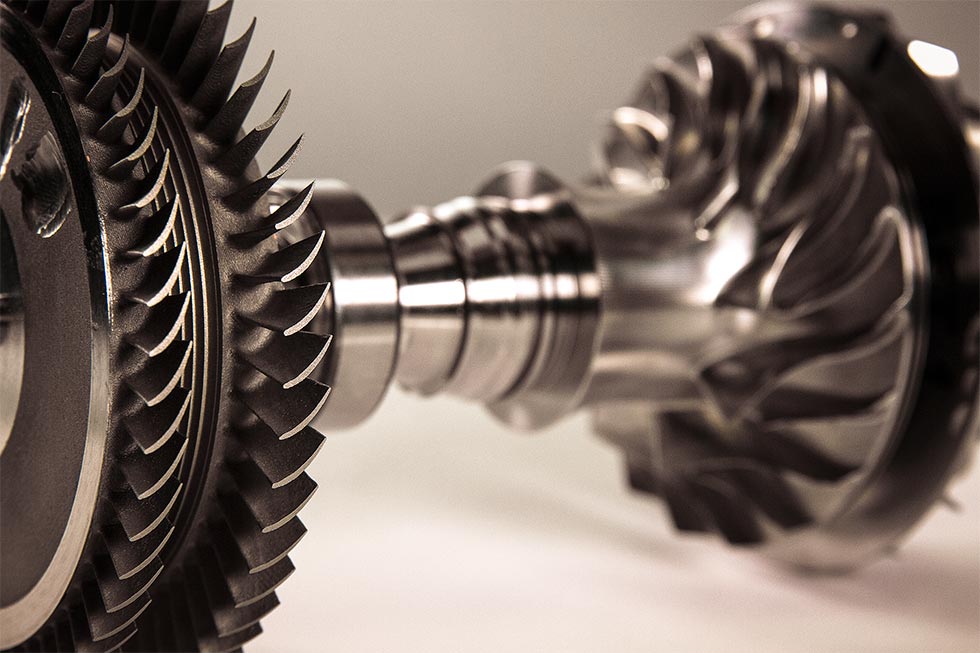

Wright’s solution lies in jet engine technology, specifically the use of small turbines as ‘range extenders’ or on-board generators with a clean burn and lower emissions than the average mix of power generation in countries burning coal.

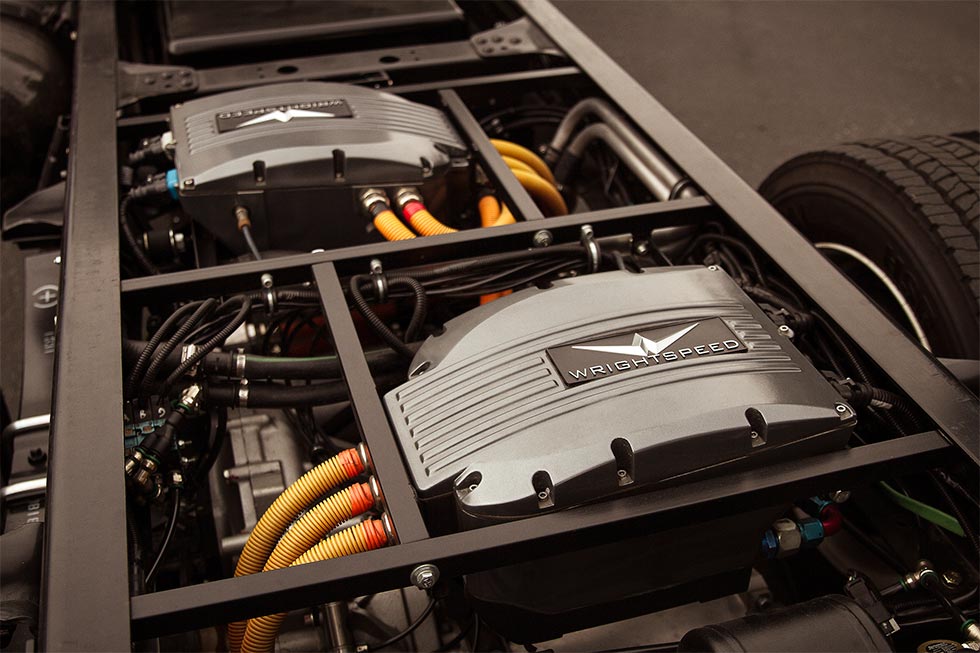

The company has designed its own electric motors, multi-fuel turbine generator, clutchless transmission and software, known as the Wrightspeed Fulcrum kit.

While it works like a traditional electric vehicle with the motors delivering drive to the wheels, when the batteries run low a small turbine kicks in providing an 80kW generator.

The low-emission turbine generator is also quiet, running only when it’s required to charge the on-board batteries.

|

|

The Wrightspeed Fulcrum turbine, which works as an onboard generator

|

This equals a cleaner net solution than plug-in electric vehicles offered by Tesla, while also improving working range, weight and charging station infrastructure concerns.

On top of energy mix issues, Wright points out that electric vehicles from manufacturers like Tesla are not only missing range extenders, but heavy-duty multi-speed transmissions, both of which Wrightspeed has managed to develop.

In terms of heavy vehicle applications, Wright explains that while systems like his range extender electric powertrain are suitable for metro applications, diesel engines will reign supreme for long haul well into the future.

“I think, in 10 years, for long haul, you’re still going to have 15-litre diesels at the prime mover — that won’t change,” Wright says.

“There will be electrification and there will be electric drive axles, there will be all kinds of interesting stuff, but that prime mover is still going to be diesel.

“I think, in 10 years, you’re going to see in urban centres pretty much all the garbage trucks will have gone to electric range extender powertrains.

“In that application, it’s just so economically compelling and when people realise it’s also so much quieter and there’s no brake dust and the emissions are so much lower … I think it will take over there within 10 years.”

Shortly after founding Wrightspeed, Wright discovered that, for heavy vehicle applications, a range extender brings a payback time that plug-in electric trucks aren’t able to offer.

“One of the things I did early in the piece is build a payback calculator that lets you vary all kinds of numbers so you can say, ‘what if I put in a bigger battery pack and I can drive more of the day on electricity I get from the grid and burn less fuel?’

“The capital cost goes up and you find pretty quickly that, at current battery and fuel prices, you’re better off and you get a shorter payback time, if you minimise the battery pack size and add range extender.

“Above a certain point payload features into the payback as well, I mean the Tesla Semi truck is going to take at least 10,000 lbs off the payload.

“If you run the payback calculator you’re forced to the conclusion that a range extender is the only economic way to do.”

|

|

The GTD Power Unit, a geared traction drive that delivers power to the wheel from the electric motor.

|

Wright says we’ll see range extended electric drivetrains both retrofitted to existing trucks, as well as the national fleet updated with new dedicated electric trucks, a trend he’s already seeing at Wrightspeed.

“I think we’ll see both and we have customers doing both.

“We started out making it available as a retrofit and the reason for that is we were a start-up company…that way we could go straight to fleet operators and offer to retrofit some of their existing fleet.

“When they liked it, then of course they said, ‘well we’re buying 5,000 new trucks a year, why can’t we get this is as part of a new truck?’

As customers began asking if the Wrightspeed system could be fitted to new vehicles, the company began talking with manufacturers.

“We started talking to the truck manufacturers and of course with low volume they don’t want to peter their production line. But, in the US at least, there’s a pretty well-developed industry for trucks and buses to do modifications after they leave the factory.”

When talking specifically about Australian applications, Wright is confident the system is suitable for Australian conditions and can be fitted in new or existing trucks.

“Of course, I think they can be installed in Australia either into new vehicles or as a retrofit.

“We do a lot of engineering work on the system to customise it for a particular chassis, so we ship it as a powertrain kit that’s targeted to a particular chassis and the kit includes everything you need to install it.

“Once we’ve done the development work for a particular vehicle, what we ship is something that can be installed quite easily in Australia”

After more than four years since delivery Wright confirms the current vehicles being used on-road have proven reliable, as interest in the technology continues to grow.

“We delivered the first two to FedEx about four-and-a-half years ago, then there’s one bus in Wellington, New Zealand, that’s on the road being tested and we’ve got one garbage truck here in the US.

“The only ones that have done a lot of time are the FedEx trucks and they’ve been reliable.”

The systems available from Wrightspeed currently range from 150hp (112kW) through to 400hp (298kW), delivering a reduction in fuel consumption of up to 67 per cent and emissions reduction of up to 63 per cent.

Wright will be discussing the future of heavy vehicle electrification and debunking myths surrounding the technology at ComVec in Melbourne next month.